Nguyên Tắc Hoạt Động Của Hộp Số Sàn. Vai Trò Của Bộ Đồng Tốc.

Mình xin chào các bạn, mình chúc các bạn một ngày gặp nhiều may mắn. Thưa các bạn, hôm trước có một bạn đã yêu cầu mình làm về cấu tạo và hoạt động của hộp số trên xe ô tô, thì hôm nay mình xin trình bày về cấu tạo và nguyên lý hoạt động chính của cái hộp số sàn, còn về hộp số tự động thì mình xin trình bày ở trong có vi-đi-ô tiếp theo.

Thứ nhất thì khi nói về hộp số sàn nói riêng và cái hộp số nói chung, thì tác dụng của nó là làm thay đổi cái lực kéo của xe, khi mà chúng ta di chuyển trong các điều kiện khác nhau và giúp chúng ta có thể lùi xe được. Mà cái việc thay đổi lực kéo được thực hiện thông qua việc kết nối các bánh răng có các cái đường kính khác nhau, thì tỉ số giữa đường kính hoặc là số răng giữa các bánh răng khi khớp nối với nhau gọi là tỉ số truyền. Thì trong từng hoàn cảnh khác nhau mà ta cần đi với các cái cấp số khác nhau, ví dụ như là khi chúng ta bắt đầu di chuyển hoặc leo dốc thì chúng ta phải đi số thấp, còn khi đi trên các con đường bằng phẳng với cái tốc độ cao thì ta phải đi số cao, thì nói chung những điều này có lẽ các bạn đã biết rất rõ thì mình xin phép không nói dài dòng nữa, mình xin đi vào cái phần cấu tạo của cái hộp số sàn, thì đối với mỗi một hãng xe thì họ sẽ có những cái cơ cấu hộp số sàn nó khác nhau.

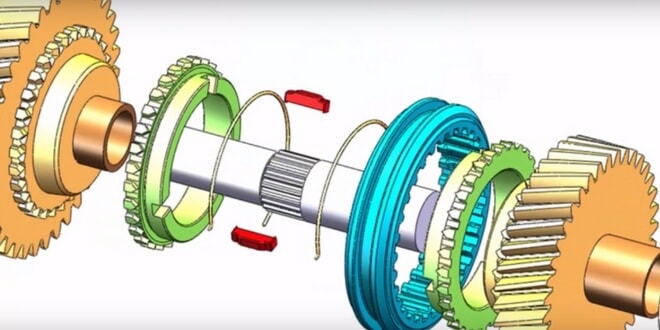

Nhưng nhìn chung thì nó cũng gồm những bộ phận chính như sau, thì trên hình là cái cơ cấu của một số sàn 5 cấp, thì các bạn thấy là cái đầu vào là bên tay trái đó là trục sơ cấp thì cái trục này nó nhận cái chuyển động từ động cơ thông qua bộ li hợp, còn cái phần trục đằng sau nó thì gọi là trục thứ cấp, và cái trục ở phía bên dưới gọi là trục trung gian, thì trên cái trục này được bố trí các cái bánh răng và nó ăn khớp sẵn với nhau, thì cái bánh răng mà ở trên trục sơ cấp với lại các bánh răng mà nằm trên ở cái trục trung gian thì nó được khóa cứng với lại trục. Thế còn các bánh răng mà nó ở trên trục thứ cấp thì nó có 2 loại bánh răng: Một là cái loại bánh răng mà khi mà ăn khớp sẵn với lại bánh răng ở phía trục trung gian thì những cái bánh răng đó là nó sẽ quay trơn và có các bánh răng mà nó được gắn cố định với lại trục thứ cấp. Nhưng mà phía ngoài của nó thì lại được lòng vào một cái tay áo, thì các bạn có thể để ý thấy những cái tay áo ở đây nó là những cái vòng kim loại mà nó có cái rãnh ở giữa, cái rãnh ở giữa nó sẽ lùa một cái thanh đòn vào đó, cái tay áo này có thể dịch chuyển dọc theo cái trục thứ cấp.

Thì khi nó dịch chuyển sang trái hoặc sang phải thì nó sẽ ăn khớp những cái bánh răng mà đang quay trơn trên cái trục đó, gắn chặt với lại cái trục thứ cấp thì từ đó nó sẽ chuyển động lực sang cái trục thứ cấp thông qua cái bánh răng đó, thì mỗi một cái tay áo thì nó sẽ có một cái cánh tay đòn, và khi mà chúng ta nắm cái cần số chúng ta di chuyển những cái cánh tay đòn này, thì những cái cánh tay đòn này nó sẽ tựa lên cái vành của tay áo và từ đó cái tay áo này nó sẽ trượt sáng trái hoặc sang phải hoặc là đứng ở giữa thì khi mà nó đứng ở vị trí giữa thì nó sẽ không ăn khớp với cái bánh răng nào cả, vậy thì cái cách thức khớp nối giữa khi một cái bánh răng mà đang quay trơn với lại một cái bánh răng được gắn cố định trên cái trục thứ cấp thì nó sẽ kết nối như thế nào với nhau? Thì chúng ta có thể quan sát cái minh họa như sau:

Thứ nhất nhìn trên hình thì chúng ta sẽ thấy là cái bánh răng màu đỏ là cái bánh răng quay trơn trên cái trục, còn cái bánh răng màu xanh là cái bánh răng được gắn cố định trên trục và cái bánh răng này thì nó được ăn khớp với lại cái tay áo ở bên trong cái tay áo nó cũng có những cái răng mà ăn khớp được với cái bánh răng cố định này, đó thì các bạn có thể quan sát là cái tay áo nó có thể trượt trên cái bánh răng ở cố định này, và khi mà nó trượt nó sẽ ăn khớp với lại cái bánh răng màu đỏ, tức là bánh răng đã quay trơn và khi đó nó sẽ kết nối hai cái thành một cái bánh răng cứng, nhưng mà một vấn đề được đặt ra đó là cái bánh răng quay trơn tức là cái bánh răng màu đỏ đấy, với lại cái bánh răng cố định trên trục thứ cấp là bánh răng màu xanh, thì khi mà chưa ăn khớp với nhau thì tốc độ của chúng là khác nhau.

Vậy chúng ta làm sao có thể khớp nối được hai cái bánh răng mà có tốc độ quay là khác nhau, liên kết lại với nhau được? Thì để giải quyết cái vấn đề này thì người ta sẽ đưa vào giữa hai cái bánh răng này một cái bộ đồng tốc, thì bộ đồng tốc thì thực ra nó là một cái vòng mỏng mà trên đó nó cũng có cái hệ thống răng, thì như các bạn quan sát thì có thể thấy là ở trên cái bộ đồng tốc thì các cái răng của nó, nó sẽ tương ứng với lại cái số răng mà của hai cái bánh răng cần khớp lại với nhau, và các cái răng mà trên bộ đồng tốc với lại các cái răng mà ở trên cái bánh răng quay trơn, bánh răng màu đỏ ý thì các bạn thấy nó sẽ vác một… ở một đầu nó sẽ bị vác đi, thì cách thức hoạt động của cái bộ đồng tốc này thì có thể mô tả như thế này:

Bài viết hay cùng chuyên mục

Khi mà cái tay áo nó cần kết nối giữa cái bánh răng màu xanh với lại bánh răng màu đỏ thì đầu tiên là nó sẽ ăn khớp trước với lại cái bộ đồng tốc, thì khi mà nó ăn khớp được với bộ đồng tốc rồi thì hai cái bộ đồng tốc và cái tay áo thì nó sẽ thành một khối thống nhất và nó đi nó áp sát với lại cái bánh răng màu đỏ, thì khi mà cái bộ đồng tốc nó áp sát được cái bánh răng màu đỏ thì với cái lực ép mà cụ thể ở đây đó là cái lực ma sát giữa bộ đồng tốc và bánh răng màu đỏ thì nó sẽ làm cho cái hệ thống này nó sẽ dính chặt vào nhau và chuyển động cùng với một tốc độ, thì khi mà nó chuyển động cùng với một tốc độ rồi, thì cái việc mà trượt với tay áo khớp với lại cái bánh răng màu đỏ thì nó sẽ dễ dàng hơn, chúng ta để ý thì là ở phần đầu của cái bánh răng màu đỏ thì các cái răng của nó, nó sẽ bị vác đi như thế này, nó bị vác chéo, cho nên là cái bộ đồng tốc mà nó có khớp với lại cái bánh răng màu đỏ ở bất kì cái vị trí nào đi chăng nữa, thì cái việc nó trượt cái tay áo lên nó đầu sẽ ăn khớp được với lại bánh răng màu đỏ.

Thì không biết mình trình bày như vậy thì các bạn có hình dung ra không? Nhưng mà về cơ cấu nó sẽ là như vậy, nó lợi dụng cái lực ma sát giữa cái bộ đồng tốc với lại các cái bánh răng thì nó sẽ làm cho chúng chuyển động cùng tốc độ với nhau, thì lúc đó việc khớp nối nó sẽ dễ dàng hơn. Thì nguyên lý của cái bộ đồng tốc này nói chung là giống nhau, nhưng mà trên mỗi một hãng xe thì người ta lại thiết kế các cái cơ cấu nó lại chi tiết nó lại khác đi một chút, thì các bạn có thể thấy là có những cái loại xe mà khi vào số nó rất là êm, còn những cái loại xe thì khi vào số nó không được êm ái cho lắm, thì đều là do cái bộ đồng tốc này cả.

Nếu mà muốn vào số một cách êm ái thì cái bộ đồng tốc này, nó sẽ phải hoạt động trơn tru, thì các bạn có thể quan sát cái minh họa ở trên thì đây là cái cơ cấu mà khi mà người ta vào số, từ số 1, 2, 3, 4 rồi là có số 5 thì với mỗi một cái tay áo ở trên trục thứ cấp thì nó sẽ ăn khớp được vào với lại hai số, tức là trượt về bên trái thì là một số mà trượt về bên phải thì là một số, thì cái việc mà trượt đi trượt lại này là nó do cái cần số của chúng ta thì nó sẽ đẩy những cái thoi đẩy, làm cho cái tay áo nó dịch chuyển, thì đấy là cái trường hợp mà số tiến còn nếu mà chúng ta có số lùi.

Tức là chúng ta phải làm đảo chiểu quay của cái trục thứ cấp, thì khi đó người ta sẽ thêm vào một cái bánh răng trung gian, thì ở đây cái cơ cấu mà thể hiện số lùi nó thể hiện ở ba cái bánh răng đó là màu đỏ, màu xanh lá cây và màu xanh da trời, thì bánh răng màu đỏ và cái bánh răng màu xanh lá cây thì được gắn cố định trên những cái trục của nó, tức là bánh răng màu đỏ nó được gắn cố định trên trục thứ cấp, còn bánh răng màu xanh lá cây thì được gắn cố định trên trục trung gian. Hai cái bánh răng này thì lúc bình thường nó sẽ không ăn khớp với nhau, chỉ khi nào mà cái bánh răng màu xanh nào nó ăn khớp với cả hai cái thì lúc đó là hai cái bánh răng này nó mới có sự chuyển động qua nhau. Thì ở chỗ này thì khi mà người ta đưa ăn khớp cái bánh răng trung gian thì người ta sẽ đẩy nguyên cả cái bánh răng đấy vào. Thì người ta thiết kế cái cơ cấu mà ăn khớp mà không có cái bộ đồng tốc như vậy là nhằm một cái mục đích tức là chúng ta chỉ có thể dừng xe hẳn thì chúng ta mới có thể vào được số lùi.

Như vậy là trên các cái xe số sàn hoặc là các cái số khác thì chúng ta không thể vào số lùi khi mà xe đang chạy được, bắt buộc là phải dừng hẳn thì chúng ta mới khớp được các cái bánh răng này vào với nhau, bởi vì giữa chúng cái cơ cấu khớp nối với nhau nó không có cái bộ đồng tốc và trong các cái quá trình gài số, thì để tránh cho những tay áo này nó trượt tự do, thì người ta bố trí ở những cái thoi đẩy, những cái rãnh, mà nó có cái viên bi và được gắn cái lò xo, thì khi mà cái thoi đẩy nó trượt thì nó chỉ có ba vị trí, nó sẽ giữ lại ba cái vị trí đó, nó là nó giữ cái vị trí, cái vị trí tay áo nó ở chính giữa khớp với bên trái và khớp với bên phải, thì khi mà đã khớp rồi thì nó sẽ tránh làm cho cái tay áo nó trượt. Thì đó là cái nguyên lý chung của cái việc gài số, thì mình nghĩ mình chỉ nên trình bày cái vấn đề này thôi, còn cái việc mà tỉ số truyển rồi cái cơ cấu bố trí cái hộp số nó như thế nào, thì các bạn có thể tham khảo ở những cái trang web người ta cũng đã trình bày rất là cụ thể về cái vấn đề này rồi.

Thì mình chỉ xét về cái khía cạnh cái cơ cấu khi nó gài số, thì cái cách gài số từ cái bộ đồng tốc nó hoạt động ra làm sao thôi, thì tiện đây mình sẽ nói thêm một số vấn đề khác về cái hộp số nói chung và hộp số sàn nói riêng, thứ nhất thì các bạn quan sát thì các bạn sẽ thấy là cái bánh răng mà khi nó ăn khớp với nhau. Thì cái hệ thống răng của chúng… của nó sẽ không được thẳng, nó sẽ vác chéo đi một chút, thì tại sao người ta lại làm vác chéo như vậy? Bởi vì, khi mà các bánh răng nó ăn khớp với nhau thì mặc dù giữa chúng là khít nhau nhưng mà thực tế nó vẫn còn cái khoản hở, thì nếu mà chúng ta thiết kế mà cái dạng bánh răng thẳng thì cái va chạm giữ các cái răng này nó sẽ tác động trực diện lên cái răng đó và nó sẽ làm cho cái răng nó nhanh bị mòn hơn. Thì người ta làm cho nó xiêng đi một chút để làm giảm cái lực tác động vô góc lên cái răng thì nó sẽ bền hơn, và khi mà ăn khớp theo kiểu xiêng như thế này thì cái cơ cấu ăn khớp vậy nó sẽ êm hơn.

Và vấn đề thứ 2 mình muốn trình bày ở đây, đó là khi mà chúng ta học lái xe thì các thầy giáo có khuyên là chúng ta lên dốc với số nào thì chúng ta sẽ xuống dốc với lại cái số ấy, thì tại sao lại như vậy? Thì khi mà chúng ta lên dốc thì chúng ta đương nhiên là sẽ cần cái số thấp, lúc mà số thấp thì cái lực kéo nó sẽ lớn, từ đó chúng ta sẽ lên dốc một cách dễ dàng hơn. Thì theo vật lý cái định luật Ba-Niu-Tơn nó nói là cái lực và phản lực nó luôn luôn đồng hành với nhau và có độ lớn giống nhau, như vậy là nếu mà lực phát động mà càng lớn thì lực cạn nó sẽ càng lớn.

Một Số Các Dịch Vụ Tại Đồng Tâm:

Do đó khi mà chúng ta xuống dốc, bởi vì chỗ thấp thì nó sẽ cho chúng ta cái lực kéo là lớn. Đồng nghĩa với việc mà cái lực cản nó tương ứng là nó cũng lớn, do đó là khi mà xuống dốc chúng ta sẽ lợi dụng cái lực cản này chúng ta di chuyển xuống dốc một cách từ từ, thì khi đó nó sẽ an toàn hơn. Nhất là trên những con đường đèo dốc mà hiểm trở, thì cái việc mà về số thấp khi xuống dốc thì các bác lái xe thường gọi đó là phanh động cơ đấy, tức là chúng ta lợi dụng cái sức cản lớn của động cơ khi mà ở số thấp để chúng ta hãm xe xuống dốc một cách từ từ. Thì trên đây mình đã trình bày về cái cơ cấu sang số của hộp số sàn, còn các cái lọa hộp số khác thì mình xin trình bày ở cái buổi sau.

Thì vi-di-ô hôm nay thì mình xin được tạm dừng tại đây, nếu có điều gì mà cần góp ý hoặc chia sẻ thì mong anh chị và các bạn hãy comment xuống bên dưới. Xin trân trọng cảm ơn sự theo dõi của anh chị và các bạn! Xin chào và hẹn gặp lại trong các cái vi-di-ô tiếp theo.

Trường đào tạo & thi sát hạch lái xe tại TP Hồ Chí Minh Trường đào tạo, dạy học và thi sát hạch lái xe máy, xe oto ở Thành Phố Hồ Chí Minh

Trường đào tạo & thi sát hạch lái xe tại TP Hồ Chí Minh Trường đào tạo, dạy học và thi sát hạch lái xe máy, xe oto ở Thành Phố Hồ Chí Minh